Hot Asphalt Concrete Special Fiber

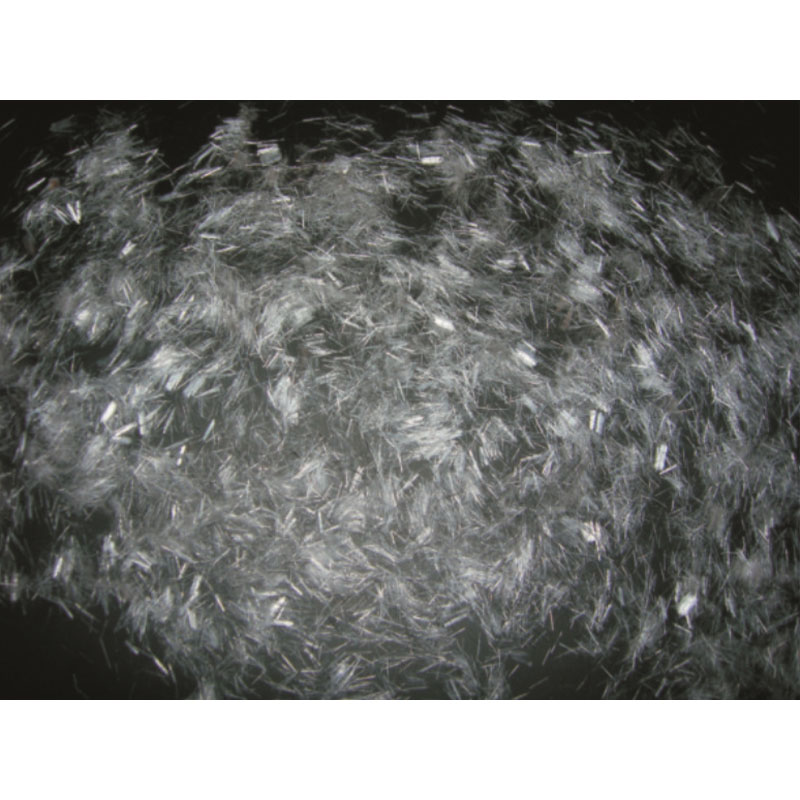

Fiber type: Polyester, polyacrylonitrile monofilament fiber, used to enhance the crack resistance of asphalt concrete, and improve the tensile, compressive and wear resistance of asphalt concrete.

Usage:

Depending on the size of traffic flow and load, the dosage of Kosili fiber can be determined accordingly. Generally, the greater the traffic volume and the greater the load, the greater the fiber dosage. The recommended fiber dosage per ton of asphalt mixture is:

1 Traffic density below 3000, the recommended dosage is 2.5 kg

2 Traffic density above 3000, the recommended dosage is 7.5 kg;

3 General traffic flow, the recommended dosage is 3.5 kg.

4 The fiber should be added to the mixer together with the hot dry material at the beginning of the mixer, and the mixing time is preferably 30 seconds; the wet mixing time is usually 30 seconds to ensure that the fiber is as evenly dispersed as possible, and the mixing temperature of the mixture with and without fiber is the same.

Benefits:

1 The tensile strength is greatly improved, increasing by about 15%;

2 The compressive strength is increased by about 15%;

3 It can improve the oiliness. If the asphalt dosage is the same, the void ratio increases by 38%, which helps to improve the thermal stability of asphalt concrete.

4 After adding fibers, the stability of asphalt concrete increases by about 0.5~1.1%, so the cracking and deformation resistance is greatly improved, which can effectively reduce the cracking caused by the reflection cracks of the road surface and the temperature difference shrinkage stress, impact damage, etc.

5 Effectively improve the adhesion, stability, rheology, and wear resistance of the road surface, effectively improve the tensile, shear, compressive and impact strength, can effectively improve the crack resistance of the road surface, improve the quality of the road surface, and effectively extend the service life of the road surface.

6 After the fiber is treated with UV protection, it has a strong anti-aging ability, and the material itself has a strong acid and alkali corrosion resistance, so the durability is reliable.

From the above analysis, it can be seen that the use of special hot asphalt concrete fiber to cover the road surface has extremely obvious engineering benefits and social benefits, and it can benefit for a long time with little one-time investment. In particular, it saves a lot of maintenance costs, and the comprehensive benefits are obvious, which is of great significance to highway construction.