For Refractory Materials, Crack-Resistant And Explosion-Proof Chemical Fibers

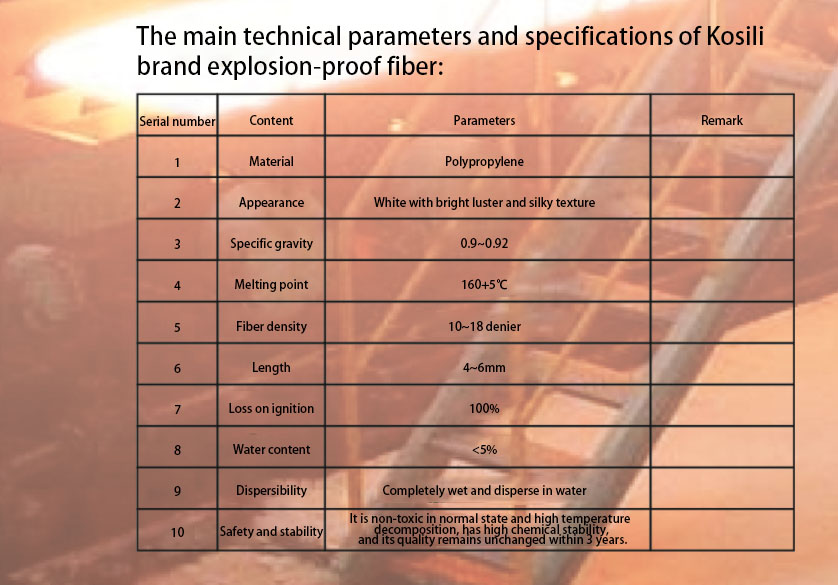

Explosion-proof chemical fiber is a special additive added to the castable during the drying process after the monolithic refractory is cast, in order to facilitate the timely discharge of water vapor from the masonry to prevent explosion. With the encouragement and support of Dr. Wang Houzhi, a professor at Wuhan University of Science and Technology and an expert in refractory materials, our institute was the first in China to successfully develop this innovative product in 1995. After repeated comparative tests and use with similar imported products, the explosion-proof effect is the same as that of imported products, but the price is much lower than that of imported products. Over the past few years, this product has been sold to many refractory factories, companies and scientific research institutes across the country, and has been recognized and praised. Now our company has perfect production technology, stable product quality, and strictly standardized product specifications and related technical parameters, so it is officially registered with the brand of Kosili explosion-proof fiber and put on the market with high standards.

Usage

1. To make it evenly mixed in the castable, it should be added to the dry material, and it is best to add it to the fine material and mix it evenly, and then stir it evenly with the coarse material.

2. To ensure that the fiber is evenly dispersed in the material, the mixing time should be appropriate.

3. The amount of additives added should be controlled appropriately. Usually for castables, according to the thickness of the masonry, it is appropriate to add (0.5~1.0%) of dry material, and for gunning materials, it is generally appropriate to add (1.0~2.0%).

Notes

1. Although adding explosion-proof fiber can prevent the furnace body from bursting during drying, the heating system of the furnace specified by various furnaces should still be followed.

2. The packaging is a woven bag with an inner liner to prevent rain and water from causing fiber agglomeration or clumps.

3. The bagged material has good dispersibility. Do not rub and stir it when opening the bag for use, otherwise it will also cause pellets that are difficult to disperse, which is not conducive to dispersion in the material.

4. Although there is no limit on the service life of this product, it is best not to exceed three years.

5. Do not store this product near high temperature (>100℃) to avoid fiber melting and adhesion and scrapping. 6. If the fiber accidentally enters the eyes, do not rub it, and it is better to rinse with water.