Polyacrylonitrile Monofilament Fiber

Polyacrylonitrile fiber has high tensile strength, large initial modulus, and stable chemical properties. Therefore, the fiber is resistant to acid and alkali corrosion, light resistance, weather resistance, and has good dispersibility. The tensile strength and elastic modulus of polyacrylonitrile fiber are much higher than those of polypropylene fiber. In practical application, it has strong bond strength with the concrete matrix, improves the adhesion and fatigue resistance of concrete, enhances the impermeability, frost resistance, and impact resistance of concrete, and makes concrete bear more load stress. Its bending toughness is more than 6 times higher than that of plain concrete.

"Technical Code for Fiber Concrete Structure, China Engineering Construction Standard CECS38:2004" stipulates that synthetic fibers used for structural reinforcement and toughening should be selected from fibers with higher elastic modulus and strength.

Usage:

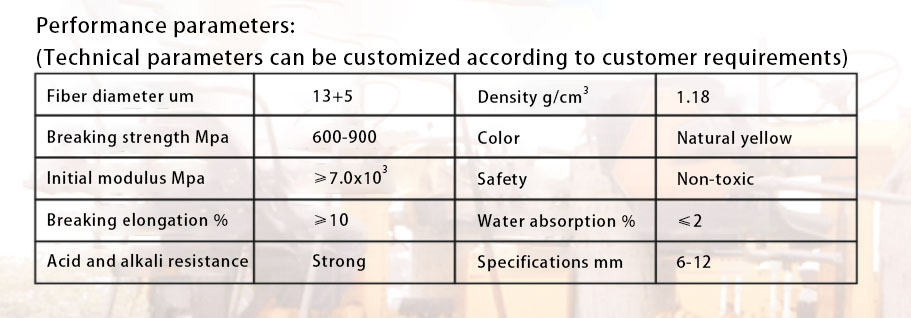

1. The recommended dosage is 0.6-1.8kg/cm*, usually 0.9kg/cm, and the dosage for bridge deck pavement with higher toughening requirements is 1.8kg/cm.

2. The length can be 6mm or 12mm, and can also be customized according to design requirements.

3. Construction instructions: There are no special requirements for mixing equipment and construction technology. During construction, the fiber is directly added to the mixer according to the mix ratio, and the mixing time can be appropriately extended to make the fiber dispersed evenly in the concrete.

Notes:

1. When fiber is added to concrete, the slump is slightly reduced, but it does not affect normal construction. If necessary, water-reducing agent can be added to adjust fluidity, and water consumption should not be increased alone.

2. The condensation performance index of fiber concrete is significantly improved compared with ordinary concrete, but fiber cannot be used as "reinforcement bar" to bear load, so the reinforcement ratio of the main force-bearing bars in the project cannot be changed.

3. After adding Dingqiang fiber, the original project structure design shall not be changed.

4. Fiber concrete/mortar needs to be maintained according to relevant national engineering standards to play its good role.

5. This product is non-toxic and has a flash point of 580℃, so it is highly safe when used.