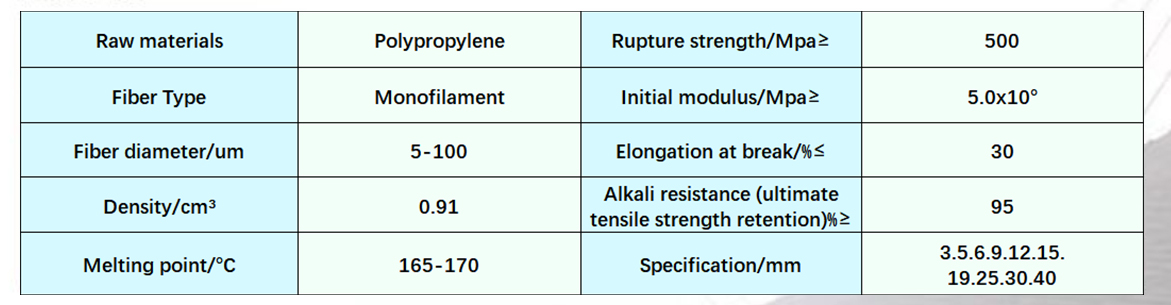

Modified Polypropylene Monofilament Fiber

Modified polypropylene monofilament fiber is a special cement concrete/mortar anti-cracking and anti-seepage fiber developed and produced by our company. After the fiber is added to the concrete, it has good dispersibility and strong bonding strength with the cement concrete matrix. It has obvious advantages of anti-cracking, enhanced anti-seepage, anti-freeze and anti-impact.

Usage:

1. Dosage: For general surface crack prevention and seepage resistance, add 0.9kg~1.2kg/m3 per cubic meter of cement concrete/mortar: 2. Proportion and mixing: Without changing the ratio of cement and sand and gravel aggregates, cement, aggregates, additives and main materials can be added together, and stirred after adding water. The stirring time can be appropriately extended for 2-3 minutes to make them fully mixed. Cement and other aggregates can also be mixed evenly, and water can be added and stirred at the construction site for use.

Precautions for use:

1. The comprehensive performance index of fiber concrete/mortar is significantly improved compared with ordinary concrete, but the fiber cannot be used as a "reinforcement bar" to bear the load, so the reinforcement ratio of the main force-bearing bars in the project cannot be changed. 2. After adding fiber, the cohesion of concrete/mortar is enhanced, and the slump is slightly reduced, but it does not affect normal construction. When the project really needs to increase the slump, the amount of water reducer should be appropriately increased, and the water consumption should not be increased alone. 3. After adding Kosili fiber, the original project structure design shall not be changed. 4. Fiber concrete/mortar needs to be maintained according to relevant national engineering standards to play its good role. 5. This product is non-toxic and has a flash point of 580℃, so it is highly safe when used.

As a high molecular polymer, Kosili modified polypropylene fiber has strong chemical stability, does not absorb water, has strong acid and alkali resistance, does not undergo any chemical changes, does not need to change its design mix ratio, and has no adverse effects on its condensation performance.

1. Improve crack resistance Kosili fiber forms a uniform random support system in concrete with a number of more than 8 million strands/cubic meter, thus producing a secondary reinforcement effect, effectively preventing shrinkage segregation, settlement and the formation and development of other cracks. After use, it is proved that under the same conditions of use, the crack resistance of concrete/mortar mixed with Kosili fiber is increased by nearly 70%.

2. Improve the impermeability. The improvement of the crack resistance of concrete/mortar by Kosli fiber can inhibit the generation of continuous cracks inside the concrete, greatly improve the compactness of concrete/mortar, and thus significantly improve its impermeability. The concrete/mortar with Kosli fiber has been proven to have an impermeability improvement of more than 70%.

3. Improve toughness, ductility, impact resistance and fatigue resistance. Kosli fiber has the advantages of large elongation, good toughness and large elastic modulus. By absorbing external forces in concrete/mortar, it avoids stress concentration and improves its ability to withstand impact loads and fatigue loads, thereby improving the plastic deformation capacity, bending tensile strength and flexural strength of concrete.

4. Improve wear resistance and peeling resistance. The addition of Kosli fiber forms an irregular random support system inside the concrete/mortar. It increases the bonding force between the mixing materials and improves the shedding of cement matrix interface particles, sand and other media.

5. Improve the freeze-thaw resistance. After adding Kosli modified polypropylene fiber to concrete/mortar, a trace amount of air can be introduced, which plays the role of aerated concrete. This can compensate for the expansion/contraction caused by freeze-thaw cycles. Some free water can also enter these tiny bubbles, thereby reducing the early freeze-thaw damage of concrete/mortar.

Packaging: 0.9kg per bag, the packaging form and specifications can be changed according to user needs.